Hookless rims: a mastered technology for gravel… but not for the road

Introduction

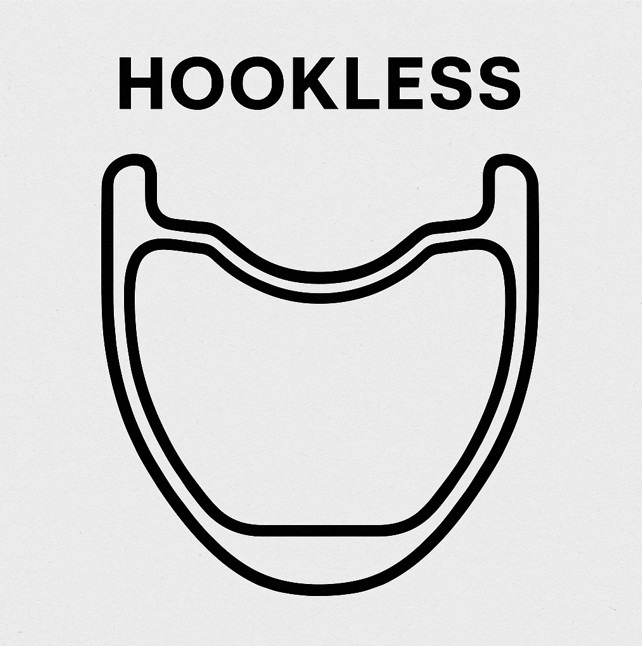

Hookless technology (hookless rims) offers clear advantages for gravel, but raises technical dilemmas for road use. GOAT Wheels, specialists in carbon bicycle wheels, have made the enlightened choice to use this technology exclusively for trail use. In this article, we first retrace the history of hookless, outline its advantages, and explain why we don’t use it on our road models.

History of hookless technology

Born with Mavic UST wheels in the 2000s for mountain biking, hookless was adopted for its robustness and ease of tire installation for use on unprepared terrain. Gradually, the major manufacturers (Enve, DT Swiss…) imported this technology into all-mountain and then gravel from 2018. It wasn’t until 2021 that some brands adopted it for their carbon road wheels, confirming its evolution to the present day.

Technical advantages adapted to gravel

Impact resistance

The straight sidewall profile of hookless rims distributes stresses more evenly, enhancing durability. On gravel roads, this geometry limits micro-cracking and improves impact behavior.

Air volume and comfort

The absence of a hook allows wider tires to be fitted at low pressure, increasing comfort, grip and vibration absorption.

Weight, simplicity and cost

Eliminating the hook saves material and simplifies manufacturing, enabling us to offer lighter, stronger carbon rims. Tire installation has also been simplified.

Why we don’t adopt hookless on the road

Despite some potential gains, hookless also presents major constraints in road use :

Limited Max Pressure

Hookless rims can withstand up to 5 bar (72 psi: ETRTO limit), which is in fact insufficient for many road tires, which go up to 7 bar depending on the rider’s weight.

Compatibility and safety

ETRTO tolerances are strict on the road. In the absence of hooks, a series of cumulative tolerances (air volume, rim dimensions, pressure, tire width) multiply the risk of dislodging while riding, in the event of a sudden puncture. Incidents among the pros (the De Gendt case in 2024 for example) have rekindled the debate. The UCI has ordered urgent expert reports, while some teams are still refusing to adopt hookless tires.

Marginal benefits

Several tests have shown that hookless does not offer any real aerodynamic benefits or significant performance on the road, making its disadvantages the main ones.

GOAT Wheels materials and design

At GOAT Wheels, hookless rims for our gravel wheels are made from high-modulus carbon fiber. These fibers are carefully selected for their excellent mechanical properties. This material, combined with a high-strength epoxy resin, guarantees an optimum balance between rigidity and shock absorption. Unlike traditional hooked rims, our hook-free profile is completely straight with thicker sidewalls, which simplifies machining and strengthens the structure. This approach preserves the rim’s structural integrity, improving its impact resistance, while ensuring lightness.

What’s more, each wheel undergoes a battery of rigorous quality controls before validation. These include pressure tests at values exceeding the manufacturer’s recommendations, fatigue cycle tests and simulations of violent impacts. All this to guarantee use in real-life conditions. These protocols, based on the most demanding standards on the market, are implemented to offer a hookless profile that is both high-performance and reliable, perfectly adapted to the constraints of gravel riding.

Assembly and maintenance: our technical tips

To guarantee rim performance and safety, it’s essential to follow a few key steps during fitting. First and foremost, choose a tire that is explicitly hookless-compatible, often identified by the TSS (Tubeless Straight Sidewall) mark. This is crucial, as not all tubeless tires are designed to work with hookless rims.

Before fitting, the rims should be thoroughly cleaned and the condition of the rim base checked. You must also ensure that the tire is properly seated and that the system is perfectly sealed. A suitable quantity of preventive fluid (generally between 30 and 70 ml, depending on the volume of the tire) should be introduced before the first inflation. Starting at around 1.5 bar, the pressure is gradually increased to the target pressure, generally between 1.8 and 3 bar, depending on the rider’s weight and the terrain.

Finally, for reliable, long-lasting use, we recommend regular checks on the condition of the tire bead, tubeless fluid level and rim cleanliness. Regular monitoring ensures consistent performance, even on the most demanding terrain.

Quick comparison

|

Use |

Hookless rims |

Hooked Rims |

|---|---|---|

|

Gravel |

✅ Robust, comfortable |

🚫Less suitable |

|

Route |

⚠️ Pressure limits at 5 bar |

✅ High pressure |

|

Tires |

From 29 mm + TSS only |

All tires |

|

Safety |

Excellent on mixed terrain |

Better Safety |

Position of GOAT Wheels

We have mastered the hookless technique and recommend it for gravel, but refuse to use it on the road, to guarantee :

Our motivation: to prioritize reliability and technical transparency, by making choices based on solid expertise.

Conclusion: technology at the service of performance

Hookless technology is a revolution for gravel, where it maximizes comfort, robustness and performance. On the road, however, its regulatory and technical constraints make it less suitable. At GOAT Wheels, we take this approach: expertise and innovation on trails with our hookless rims for gravel, caution and reliability on asphalt.